Electric motor manufacturer Donut Lab has shown off its latest innovation at CES 2025.

The company’s second-generation in-wheel drive units could drastically alter the way electric vehicles are designed.

The new motor seemingly draws inspiration from the company’s namesake – a big hole in the middle allows it to fit perfectly into a wheel. According to Donut Lab, this will reduce a lot of weight, while providing great gains in power and torque.

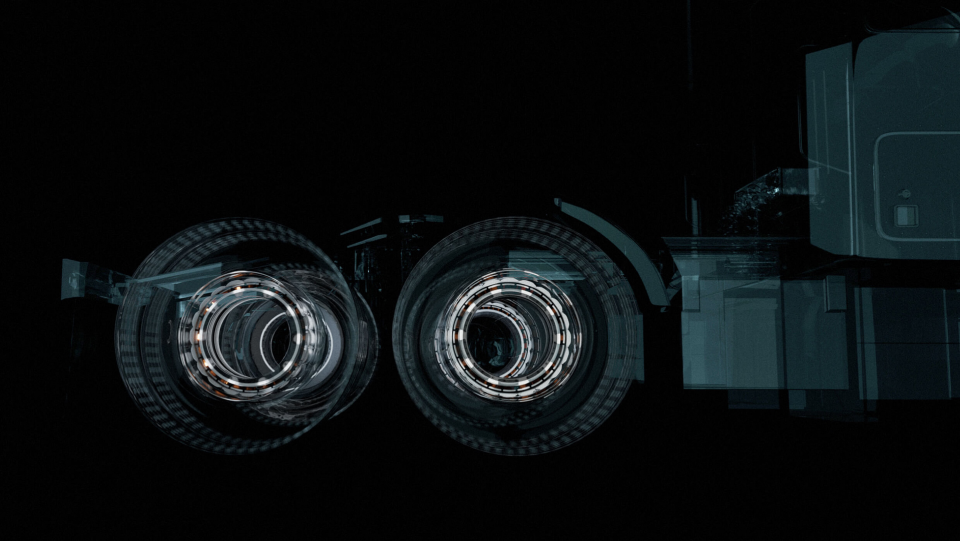

Donut Lab’s new in-wheel motor

To date, the EV industry has taken a great deal of inspiration from the design of internal combustion engine (ICE) vehicles. That’s logical, given the fact that EVs are an iteration of ICE vehicles. That familiarity in design can also help with global EV adoption, which slowed down slightly in 2024.

However, electric motors allow for far greater design adaptability than ICEs. Case in point: Donut Lab’s second-generation donut-motor. The in-wheel design means no motor is housed in the vehicle’s body. This frees up space, allowing for more seating area and cargo capacity.

It could ultimately allow for some pretty wild designs, resembling some of the crazy concept vehicles often on display at trade shows.

Donut Lab says its second-generation donut motor fits into a 21-inch hoop. It delivers a performance of up to 630 kilowatts (845 horsepower) and 4,3000 newton-meters (3,171 pound-feet of torque) per unit. Impressively, the motor weighs only 88 pounds (40 kg). According to a report from CNET, that’s equivalent to roughly a third of a traditional rotor-and-stator electric drive unit.

Lowering weight is crucial to increasing EV range. While EVs will require more than one of Donut Lab’s motors, the resulting removal of drivetrain components, half-shafts, and other parts will result in even greater weight savings.

New in-wheel motor is 50% cheaper to manufacture

Donut Lab also says its motors are up to 50 percent cheaper to manufacture. This is largely down to the fact they use fewer parts, the company says. This could ultimately result in more affordable EVs.

However, questions do remain over the performance of Donut Lab’s in-wheel motors. While they reduce overall weight, they are heavier than conventional wheels. This means they add unsprung mass – weight below the suspension – which can negatively affect handling and braking.

Aside from its new 21-inch in-wheel motor, Donut Lab also revealed a new semi-truck version of its in-wheel motor. This will provide 200 kW and 2,212 lb-ft (3,000 Nm) per wheel. The company’s in-wheel motor technology is already used on the road on a few electric bikes developed by its parent company, Verge Motorcycles.

Donut Lab isn’t the only company experimenting with in-wheel motors. Last year, BMW announced it had developed its own in-wheel electric motor in partnership with Munich-based tech firm DeepDrive. That motor features a unique dual-rotor design and is currently in the testing phase.

#donutshaped #inwheel #motor #EVs #lighter #increase #range

Leave a Reply